Engine Condition Trend Monitoring (ECTM) - آزمایشگاه شبیهسازی دینامیک شارهها و علوم گرمایی cfdtherms

ٍEngine Condition Trend Monitoring (ECTM)

The practice of monitoring the condition trends of engines is essential for ensuring optimal performance and longevity. This process involves the systematic observation and analysis of various parameters that indicate the health and functionality of an engine over time. By employing advanced diagnostic tools and techniques, engineers can identify potential issues before they escalate into significant problems, thereby enhancing reliability and reducing maintenance costs.

Engine condition trend monitoring encompasses a range of activities aimed at assessing the operational state of an engine. This includes the collection of data related to temperature, pressure, vibration, and other critical indicators that reflect the engine's performance. By analyzing these data points, professionals can detect deviations from normal operating conditions, allowing for timely interventions and adjustments that can prevent catastrophic failures and extend the engine's service life.

The implementation of engine condition trend monitoring not only contributes to improved safety and efficiency but also supports informed decision-making regarding maintenance schedules and resource allocation. Organizations that adopt this proactive approach can benefit from reduced downtime and enhanced productivity, as they are better equipped to anticipate and address potential issues. Ultimately, this strategic focus on monitoring engine conditions fosters a culture of continuous improvement and operational excellence within the industry

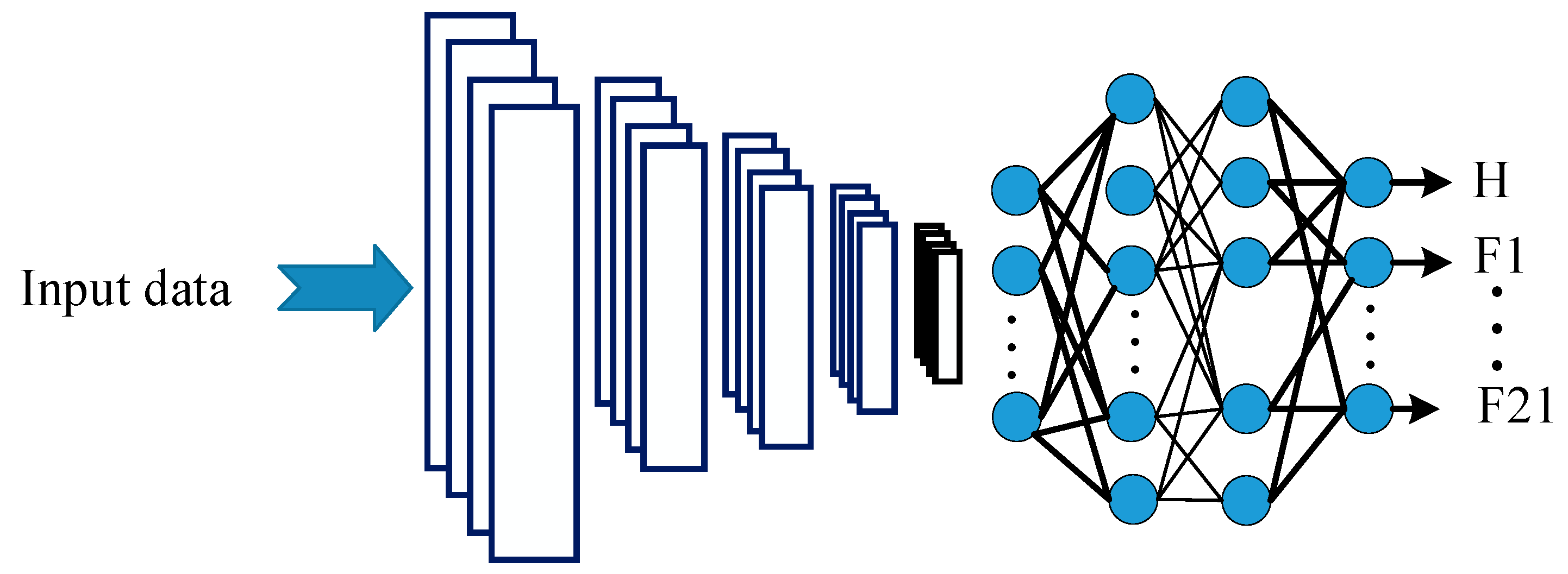

The utilization of machine learning techniques for monitoring the condition trends of engines represents a significant advancement in predictive maintenance and operational efficiency. By leveraging sophisticated algorithms, organizations can analyze vast amounts of data collected from engine sensors and operational parameters. This approach enables the identification of patterns and anomalies that may indicate potential issues, allowing for timely interventions and reducing the risk of unexpected failures.

Implementing machine learning for engine condition trend monitoring involves the integration of various data sources, including historical performance metrics, real-time sensor readings, and environmental factors. The algorithms can be trained to recognize normal operating conditions and detect deviations that could signify wear and tear or impending malfunctions. This proactive strategy not only enhances the reliability of engine systems but also optimizes maintenance schedules, ultimately leading to cost savings and improved safety.

As industries increasingly adopt digital transformation strategies, the role of machine learning in engine condition monitoring is becoming more prominent. The ability to continuously learn from new data allows these systems to adapt and improve over time, ensuring that maintenance practices remain effective in the face of evolving operational challenges. Consequently, organizations that embrace this technology can expect to achieve greater operational resilience and a competitive edge in their respective markets.